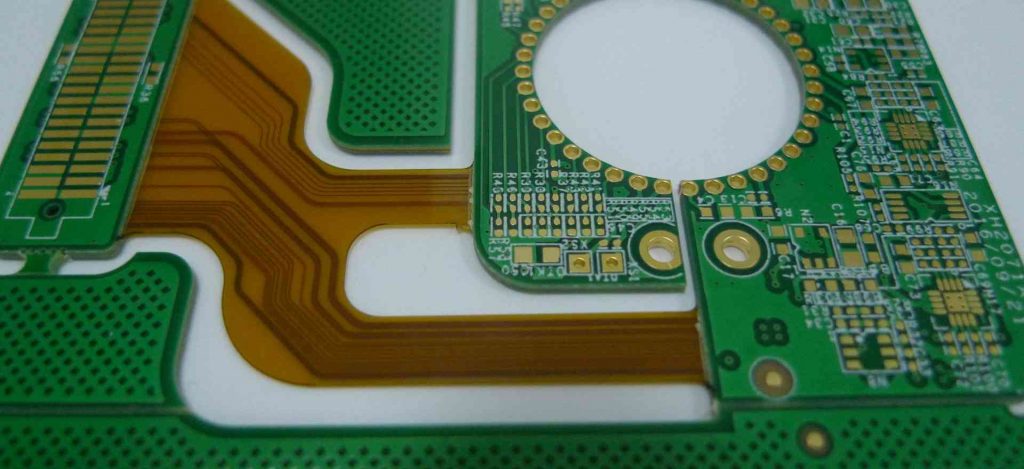

Shenzhen Fumax Technology Co., Ltd is one of the leading manufacturers of lightweight, yet high performing flexible printed circuit boards in the US. We provide these circuit boards in different specifications. Our in-depth technical knowledge, and well-equipped facility enable us to assure shortest turnaround times on all types of printed circuit boards including 6 layer flexible printed circuit boards. These circuit boards have six conductive layers that are placed on an extremely flexible substrate.

The PCB is created using a polyimide, which is a thermally stable alternative to FR4 designs. It also helps increase its heat dissipation capability. We provide the PCB with immersion gold surface finishing, which helps increase its surface planarity. Other advantages of availing this surface finish include increased oxidation resistance and improved usability for contact surfaces that are untreated. These PCBs can be provided with other surface finishing options, including HASL and OSP on request. All these surface finishes help improve the shelf life, as well as durability of these circuit boards.

Flexible circuits, also known as flex PCBs, are printed circuit boards that can be bent, twisted and folded because they have a substrate of flexible polyimide film and one or more thin layers of metallic material (usually copper). The copper layers are chemically etched to produce the desired circuit patterns. Adhesive is commonly used to bond the copper to the polyimide film, but other types of bonding can be used

Shenzhen Fumax Technology Co., Ltd PCBs provide the ability to integrate multiple rigid PCBs interconnected using flexible circuits in a single assembly. The combination of rigid and flexible materials in one board allows three-dimensional packaging and increased component density within electronic devices.

There are different kinds of flexible circuits, including single sided, double sided, multilayer and flex circuits.

Single Sided Flexible Circuits

They consist of a layer of copper and a layer of dielectric material (flexible polyimide film) bounded together. A coverlay is added to the flex circuit for insulation and protection.

Double Sided Flexible Circuits

They consist of two layers of copper separated by a single layer of dielectric material. Plated through holes are used to make electrical connections between the two layers.

Multi-layer Flexible Circuits

They consist of three or more layers of copper separated by layers of dielectric material. Plated through holes are used to make electrical connections between the two layers.

Benefits of 6 Layer Rigid-Flex PCBs

Compared to conventional rigid boards, 6 layer rigid-flex PCBs offer the following advantages:

Increased Component Density

Folding rigid sections vertically allows placing components on both sides of stacked boards for space and height reduction.

Simplified Assembly

Replacing discrete flexible cables and wire harnesses with integrated flexi-rigid board reduces assembly labor and errors.

Enhanced Flexibility

Eliminates inter-board connectors by running flexible circuits between rigid sections. Accommodates complex motion paths.

Improved Serviceability

Modules can be independently removed for repair/upgrade without affecting other sections by separating along flex bends.

Reduced Weight

Inter-board cables have heavier insulation than thin flexible layers. Removes extraneous housing needed for discrete cables.

Lower Costs

Fewer connectors, simpler assembly, higher density save on materials cost and manufacturing expenses.

Signal Integrity

Better high speed performance by minimizing discontinuities through maintained impedance in traces spanning rigid and flex sections.

Reliability

Avoids reliability risks associated with external wiring and interconnections.

Applications of 6 Layer Rigid-Flex PCBs

rigid-flex-pcb-design

The unique capabilities of rigid-flex make them ideal for the following applications which require packaging density, versatility and reliability:

Wearable devices

Medical electronics

Consumer gadgets

Robotics and UAVs

Automotive electronics

Industrial equipment

Military systems

6 layer rigid-flex technology provides adequate routing channels to implement complex high density circuits for such miniaturized and high performance products.

Rigid-Flex PCB Construction

6 layer rigid-flex consists of:

Multiple layers of copper clad rigid FR-4 material

Layers of adhesive-based flexible dielectric like polyimide

Coverlay bonding the flexible layers

The main rigid section has 6 copper layers. The flex sections integrate 2-6 layers depending on routing needs. Sections are held together by an adhesive. Plated thru holes provide interconnects between layers.

Rigid sections provide mechanical strength for component mounting and heatsinking. Flex layers enable out-of-plane motion and 3D assembly. Different rigid and flex materials can be combined for optimal electrical and thermal performance.