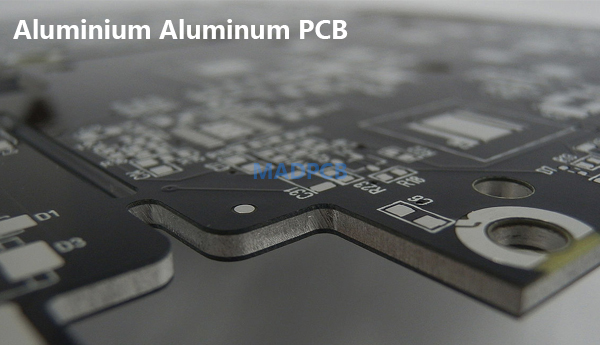

Aluminum PCB, or Aluminium PCB, also called Alu PCB, is one of Insulated Metal Substrate (IMS) PCBs, and is also one of the most commonly used Metal Core PCBs (MCPCB) nowadays. MADPCB manufactures Aluminum printed circuit boards (PCB) with a full selection of high-performance substrates, and we work to be the best aluminum PCB manufacturer and provider no matter you need prototypes or high-volume production quantities. Aluminum PCBs typically are single-sided, but also can be double-sided as well. While, multilayer Aluminum PCBs are highly difficult to manufacture.

According to the construction and design, aluminum PCBA can be divided into different types. After studying all following types, we can see that aluminum PCBA have many characteristics in same, such as that the main purpose is to provide heat dissipation solutions for the applications involving high temperature.

The multiplayer Aluminum PCB is typical one in power supply applications with multiple layers of thermally conductive dielectrics. These materials are very useful when they are combined with one or more layer of circuitry in which thermally conductive dielectric is buried between the layers with the help of blind vias which also act as a signal or thermal vias. It’s extremely helpful when provide an ideal solution for many applications concerning heat dissipation.

As a new addition in the development of aluminum products, flexible aluminum PCBA increasingly be applied in heat dissipation products. These materials come with polyimide resin integrated with ceramic filters which exhibit high flexibility, thermal efficiency and excellent electrical insulation. When it applied with aluminum material, the final product will save costly cables and connectors, and will bring more flexibility.

When it comes to more complex constructions, as the production of through Hole Aluminum PCB, a single layer of aluminum is back-filled and pre-drilled with before applying lamination, forming a core of multiplayer constructions. Thermal bonding materials are then used to laminate the thermal materials on both sides of the aluminum. Once lamination is done, drilling is applied on the assembly. In order to maintain proper electrical insulation, the plated through holes are created as the result of drilling must pass through aluminum clearances.

Rigid aluminum PCBs – Most aluminum PCBs are rigid and have good mechanical strength. They can be 1-layer, 2-layer with one component-mounting side, 2-layer with two component-mounting sides, and 4-layer with two component-mounting sides. We can customize the power of the aluminum PCB from 1W/mK to 9W/mK for you.

● Flexible aluminum PCBs – If the aluminum PCB laminate has higher aluminum content, the board can bend, and it can be used for LED lights that can illuminate in all directions. Flex aluminum PCBs have only one layer, the power of 1W, and their surfacer finish can only be OSP. And we suggest 0.5oz copper thickness for them

HOW ARE ALUMINUM PCBS MADE?

A thin layer of thermally conductive but electrically insulating dielectric is laminated between a metal base and a copper foil. The copper foil is etched into the desired circuit pattern and the metal base draws heat away from this circuit through the thin dielectric

BENEFITS OF ALUMINUM PCBS

Heat dissipation is dramatically superior to standard FR-4 constructions.

The dielectrics used are typically 5 to 10 times as thermally conductive as conventional epoxy-glass and a tenth of the thickness

Thermal transfer exponentially more efficient than a conventional rigid PCB.

Lower copper weights than suggested by the IPC heat-rise charts can be used.

Advantages and Applications

Aluminium-based PCBs can consistently increase durability and long-term reliability of a final product through temperature control and associated reductions in failure rates. Aluminum designs also deliver better mechanical stability and lower thermal expansion levels than conventional PCB materials.

Improved Product Durability

Increased Power Density

Increased Thermal Efficiency

Reduced Number of Interconnects

Lower Junction Temperatures

Reduced PCB Size

Eliminates Older Hardware

Minimizes Labor Required for Assembly

Wide Variety of Form Factors

Minimize Thermal Impedance

Applications of Aluminum PCBA

Telecommunications, including high-frequency amplifiers and filtering appliances

Power Supply, such as switching regulators and DC/AC converters

Automotive, including electronic regulators, lighting and power controllers

Computers, such as CPU boards, floppy drives and power devices

Power Modules, including converters, solid-state relays, power rectifiers, and bridges

Audio Devices, such as input and output amplifiers and power amplifiers

Office Automation, such as electric motors and drives

Consumer: Street lighting, Traffic control lighting, Interior building lights, Landscape lighting, and Camping gear.

Medical: Operating room lighting, Surgical lighting tools, High power scanning technology, and Power converters.

MODERN SOLUTIONS FOR YOUR PCB CHALLENGES

Shenzhen Fumax Technology Co., Ltd is one of the leading suppliers of Printed Circuit Boards. Shenzhen Fumax Technology Co., Ltd is a long established and globally positioned supplier of Printed Circuit Boards whose mission is to utilize its long experience and history to increase our customers competitiveness and improve their time to market.