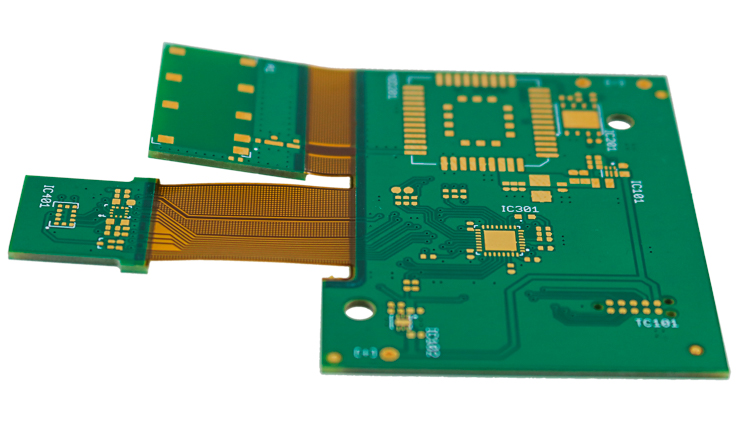

What is a Rigid Flex PCB?

Rigid-flex PCBs are new creative types of PCBs that own the convenience of rigid PCBs and the high flexibility and adaptability of flexible PCBs. Among all PCBs, rigid-flex can withstand seriously tough application environments, which is favored by high-end industrial control and the medical industry. Rigid-flex PCBs differ from the original flex board and rigid board in raw material and manufacturing processes. Rigid-flex PCBs own the advantage of both rigid FR4 PCBs and flexible PCBs. In the rigid space, where electrical and electronic components will be soldered on, the whole board can bend in the flexible PCB space. That is to make the assembly more flexible and space-saving and keep tight trace designing.

Rigid flex printed circuit boards are boards that use a combination of flexible and rigid board technologies. Most rigid flex boards consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

Rigid flex designs are more challenging than the design of a typical rigid board environment, as these boards are designed in a 3D space, offering greater spatial efficiency. By being able to design in three dimensions designers can twist, fold and roll the flexible board substrates to achieve their desired shape for the final application’s package.

Rigid Flex Capabilities

We build relationships with the best rigid flex PCB manufacturers available so we can provide you with the best product for your applications. We can provide rigid flex for complex multilayer commercial applications or high-reliability MilSpec printed circuit boards. Whatever your rigid flex PCB needs are, we can facilitate this process and ensure you get exactly what you need in a short amount of time.

We can turn your rigid flex PCBs in as fast as 48 hours.

Advantages of Rigid-Flex PCBs

The benefits of Rigid-Flex PCBs are below:

Save space and weight by applying 3D and removing connectors

Assure higher reliability with fewer solder joints

Simplified assembly and test processes.

Provide simple modular interfaces to the system environment.

Adapt to more complexity of mechanical designs

Space requirements can be minimized by applying 3D

By removing the need for connectors and cables between the individual rigid parts, the board size and overall system weight can be reduced.

By maximizing space, there is often a lower count in parts.

Fewer solder joints assure higher connection reliability.

Handling during assembly is easier in comparison with flexible boards.

Simplified PCB assembly processes.

Integrated ZIF contacts provide simple modular interfaces to the system environment.

Test conditions are simplified. A complete test before installation becomes possible.

Logistical and assembly costs are significantly reduced with Rigid-Flex boards.

It is possible to increase the complexity of mechanical designs, which also improves the degree of freedom for optimized housing solutions.